Toyoda Horizontal Machines

Choose from a package of different configurations

Full Line of Horizontal machining centers

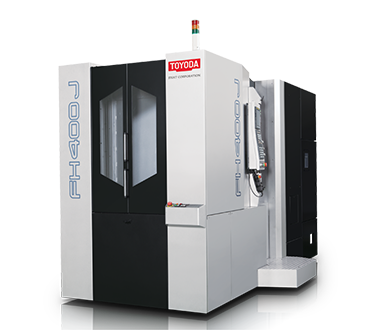

Model – FH400j & FH450S Series

Specification

The FH400J is a compact, high-speed horizontal machining center featuring a 15,000 RPM spindle, tool-to-tool cycle time of .9 seconds, and a rapid feedrate of 2,362 ipm (60 m/min).

Model – 500 / 550 Series

Specification

A step up from a 400 mm size machine, the Wele HMC500 offers larger work envelope and superior production value for high-speed operations. The HMC500 features a 30 HP, 15,000 RPM built-in motor style, with 3.3 seconds ramp up 0 to 15,000 high-speed spindle makes the most of your production.

Full Line of Horizontal machining centers & 5-Axis

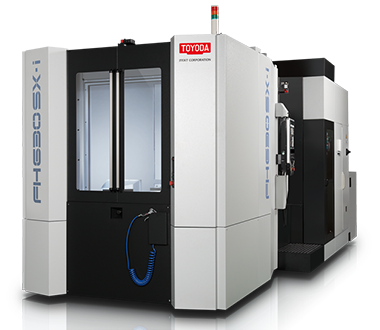

Model – FH-630 Series

Specification

The FH630SX-i is a powerful, high-speed horizontal machining center featuring an 8,000 RPM spindle, with the option of a 15,000 RPM high-torque spindle, and a rapid feedrate of 2,362 ipm (60 m/min). This machine has dual ballscrew drive on the Y and Z axes, and a Meehanite cast iron base for improved rigidity.

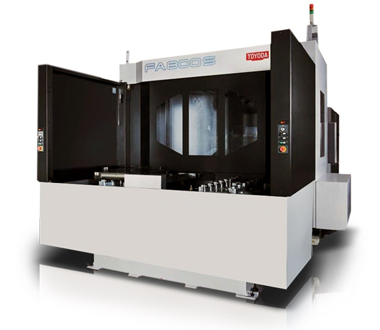

Model – FH / FA 800 Series

Specification

The FA800S is a heavy-duty horizontal machining center featuring a 6,000 RPM direct-drive spindle, with options of a 6,000 RPM geared-head spindle or 15,000 RPM spindle, and a rapid feedrate of 944 ipm (24 m/min). The machine’s robust column and bed, box guideways, and large workpiece swing allow for powerful machining with high accuracy.

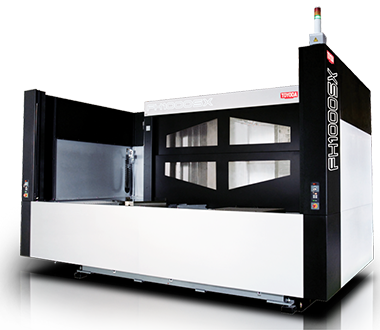

Model – FH / FA 1000 & 1050 Series & 5-Axis

Specification

The FH1000SX is a powerful, high-speed horizontal machining center featuring a 6,000 RPM spindle, with options of an 8,000 RPM or 15,000 RPM high-torque spindle, and a rapid feedrate of 2,126 ipm (54 m/min). This machine has dual ballscrew drive on the Y and Z axes, and a Meehanite cast iron base to suppress vibration in the heaviest of cuts.

Full Line of Horizontal machining centers & 5-Axis & Horizontal boring Mills

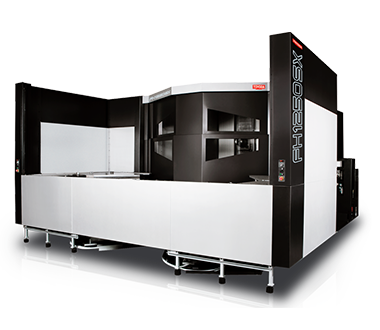

Model – FH 1250 Series

Specification

The FH1250SX is a powerful, high-speed horizontal machining center featuring a 6,000 RPM spindle, with options of an 8,000 RPM or 15,000 RPM high-torque spindle, and a rapid feedrate of 1,654 ipm (42 m/min). This machine has cylindrical roller guides for increased speed, and dual ballscrew drive on the Y and Z axes and a Meehanite cast iron base for maximum rigidity.

Full Line of Horizontal machining centers & Horizontal boring Mills

Model – FH1600SW-i

Specification

Toyoda’s FH1600SW-i horizontal machining center features the largest work envelope in its class with a maximum swing of ⌀126″ (⌀3,200 mm) and a workpiece height of 83″ (2,100 mm). Engineered for heavy cutting, the FH1600SW-i’s 5.9″ (150 mm) diameter quill spindle allows for powerful cutting with high material removal rates.

Full Line of 5-Axis

Toyoda 5-Axis Machining Models

Specification

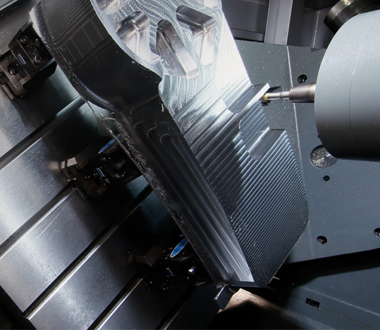

Reduce the high cost and risks from preparing multiple set-ups with 5-axis machining. Toyoda offers a wide series of machine with revolutionary 5-axis technology providing you with the capability to machine complex shapes efficiently in a single set-up.