5 Axis Mills

Choose from a package of different configurations

Builders with 5-Axis Machines Centers

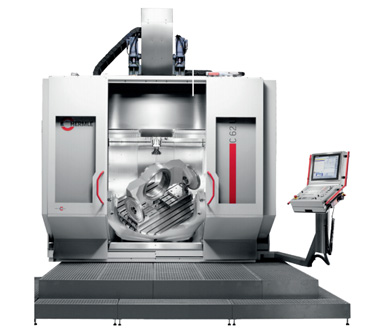

C 62 / C 62 U MT machining centre – the applications

HERMLE HIGH-PERFORMANCE-LINE

‘State-of-the-art’ CNC machining – this is what the C 62 / C 62 U MT stands for as Hermle’s High-Performance-Line flagship at the top of the entire product range. The highly dynamic machining centre represents ultimately consistent design for efficient machining of CNC milled parts and CNC turned parts. The application clips show the details of how this works in practice.

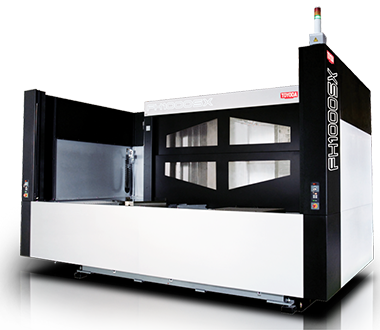

Model – FH / FA 1000 & 1050 Series & 5-Axis

The FH1000SX is a powerful, high-speed horizontal machining center featuring a 6,000 RPM spindle, with options of an 8,000 RPM or 15,000 RPM high-torque spindle, and a rapid feedrate of 2,126 ipm (54 m/min). This machine has dual ballscrew drive on the Y and Z axes, and a Meehanite cast iron base to suppress vibration in the heaviest of cuts.

Contact Us

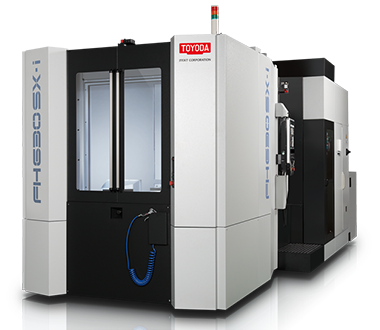

Model – FH-630 Series

The FH630SX-i is a powerful, high-speed horizontal machining center featuring an 8,000 RPM spindle, with the option of a 15,000 RPM high-torque spindle, and a rapid feedrate of 2,362 ipm (60 m/min). This machine has dual ballscrew drive on the Y and Z axes, and a Meehanite cast iron base for improved rigidity.

Contact Us

Tongtai CT Series – 5-Axis Built-in Trunnion Table Vertical Machining Centers

Tongtai CT Series high-speed, high-accuracy 5-axis trunnion table machining centers are engineered for complex machining of mold, die, aerospace and medical parts.

X, Y, and Z axis travels are 15.7″ x 20.1″ x 20.1″ (398 mm x 510 mm x 510 mm) respectively. A 20 hp, 15,000 rpm direct drive spindle provides both low end torque and high speed finishing ability via high/low winding switching. Both Big Plus 40 taper or HSK-63A toolholding is available. A 20,000 rpm integral spindle is optional.

Rapid traverse rates are 1,417 inch/min (36 m/min) in X and Y and 1,181inch/min (30 m/min) in Z. Linear axes have 45mm (1.77″) – dia. roller-type guideways, and tilt and rotary axes employ a zero backlash roller gear mechanism. Large diameter 40mm (1.57″) in X and Y and 45mm (1.77″) in Z double anchored and pre-tensioned ballscrews with least increment input of .0001mm/ .00001″ provide positioning accuracy of +/-0.00012″ (0.00304 mm) and repeatability of 0.0001″ (0.00254 mm).

Contact Us

Tongtai MDV and GT Series 5-axis Trunnion Table Machining Centers

The four-machine Tongtai MDV and GT Series of high speed, high accuracy 5-axis trunnion table machining centers is engineered for complex, precise machining of mold, die, aerospace and medical parts. The machines have heavy Meehanite castings, roller-type linear guideways in linear axes, and zero-backlash roller gear mechanisms in tilt and rotary axes to maximize rigidity and precision. Large diameter double-anchored and pre-tensioned ballscrews with least increment input of 0.0001mm/ 0.00001″ produce positioning accuracy of +/- 0.003mm (0.00012″) and repeatability of 0.0025 mm (0.0001″) with scales.

Contact UsBuilders with 5-axis CNC Turning centers

Tongtai TMS Series 5-Axis Mill/Turn Centers feature B-Axis Head & 75 Degree Slant Bed Design

Tongtai TMS Series mill/turn machines are available in 4 different models, each available in 3 different configurations with up to 9 total axes. The standard TMS machine has a programmable tailstock. The TMS-S has a sub-spindle in place of the tailstock, and the TMS-ST features both a sub-spindle and a lower turning turret. Maximum turning diameter for the machines is 25.98″ (660 mm) with bed lengths up to 80” (2000mm).

The TMS Series consists of the TMS-2000 (8” chuck, 2.5” bar), TMS-2500 (10” chuck, 3” bar), TMS-3000 (12” chuck, 3” bar), and TMS-3800 (15” chuck, 3.5” bar).

Contact Us

QuickTECH S-32 & S-42 ATM Compact 9-Axis Twin Spindle Mill/Turn Centers with B-Axis & ATC

The QuickTECH S-32 ATM is compact mill/turn center for small, complex parts. It combines precision integral motor main and sub spindles for turning with B-axis milling head and ATC to produce complex parts. Utilizing a unique 3-axis movement of the sub-spindle, machine physical size is minimized by the sub-spindle’s ability to move in the X-axis above and below the center line out of the way of the B-axis milling spindle. This high production CNC turning center is cast from Meehanite iron. With a 30mm bar capacity, this unique bar processing center provides complete part machining including all complex milling functions. The S-32 ATM features 9 total axes, 2 turning spindles, a B-axis milling spindle with 24 tool auto tool change, and 6 fixed sub-spindle turning tools for a total capacity of 30 tools.

Contact Us