Muratec

Choose from a package of different configurations

Full Line of Twin Spindle Machines

Our newest and most eco-friendly machine, the MW35 is an all-electric turning center that can create fasteners and other small parts in as little as three seconds! Additionally, MW35’s compact footprint provides the ultimate reduction in floorspace usage.

Know more

The Muratec MW40 is an extreme-precision compact turning center capable of repeatability in the single digit micron level.

For small, high precision components in medium to large lot sizes, you can’t beat this machine’s extreme accuracy.

Know more

Experience lightning-fast part to part cycle times with the compact MW50.

For 50mm diameter parts, the MW50 delivers flexibility, versatility and a gang style tooling block for quick tool changes.

Know more

Based on a gang-tool platform and designed for increased productivity.

The MW80 is equipped with two horizontal spindles and twin four-station tool blocks. The same lightening speed as the MW50, the MW80 can accommodate parts up to 80mm.

Know more

Produce parts in as little as 16 seconds with the MW100.

The MW100 is a twin spindle turning center that improves productivity with exceptional rigidity and high precision processing. This machine is a great fit for customers seeking to save space in production setup. Find out how the MW100 can work for you!

Know more

The MW120 machine is designed for high-volume production of various part types.

With a twin spindle design, this machine offers unmatched part production efficiency. Unlike similar models on the market, the MW120 is entirely self-contained, allowing operators to turn highly accurate parts from a single source machine.

Know more

Reduce idle time by up to three seconds per part with our fastest-ever automated turning center.

Armed with a high-speed, lightweight gantry loader, the MW120II boasts traverse speeds 1.5 times faster than a traditional gantry loader.

Know more

Designed specifically to turn high precision parts, the MW120EX can eliminate the grinding process and perform hard turning operations.

Paired with our automation solutions, this machine delivers ultra-precise performance with unbeatable efficiency.

Know more

Equipped with a high-speed gantry that can pick up parts of different weights and sizes, the MW180 is the ideal solution for multi-part manufacturers.

This self-contained machine offers optimal flexibility, and reduces cycle times for improved productivity.

Know more

The flagship model of the MW Series, you can count on the MW200 to deliver speed, flexibility, precision, and reliability in every single cycle.

Offering rapid load/unload times, this customer favorite can perform multiple processes from a single source.

Know more

The MW400 is the largest machine in our MW Series and was designed for heavy-duty cutting of large parts.

Delivering exceptional rigidity and high-precision processing this machine features a newly designed CNC controlled gantry for even higher speed and versatility.

Know more

Full Line of Single Spindle Machines

The MS20G is a single spindle CNC turning center and is ideal for automation, line planning and system integration.

This machine can be combined with the twin spindle turning centers within the MW Series for increased productivity and a better working environment.

Know more

The single spindle CNC turning center, MS50, delivers exceptional rigidity, high precision processing, and greater productivity.

With a high-speed loader and versatile automation, this machine features quick load/unload times at a fraction of the usual production time.

Know more

The MS60’s compact size paired with its high-speed capabilities provide ultimate efficiency for high-volume production.

Complete with an automated gantry loader and a maximum traverse speed of 150 m/min, this machine first in class for versatility and efficiency.

Know more

The MS90 is a single spindle CNC turning center than can perform third operations at incredibly high speeds.

Like all of the machines in our MS Series, the MS90 is frequently used for line planning alongside a twin spindle turning center from our MW Series.

Know more

The MS100G is a single spindle CNC turning center, delivering revolutionary results to automated line systems.

Though this machine can accommodate the largest parts within our MS Series, its compact size makes it a great selection for those seeking to save space in production. Find out if it’s the right fit for you!

Know more

Full Line of Live Tool Machines

The MD60 single spindle CNC turning center is the ultimate solution for multi-processing turning.

A top-performer of our MD Series, this machine features live-tooling capabilities, including milling and drilling, and can perform both low- and high-volume tooling projects.

Know more

The MD100 is a single spindle CNC turning center with integrated live-tooling capabilities combining multiple operations into one, highly accurate machine.

A next-generation solution for lean manufacturing systems, the MD100 features a compact design to increase efficiency and improved productivity.

Know more

Suitable for various types and patterns of production, the MD120 is a versatile solution for a unique requirements and configurations.

With two spindles and the automatic part turnaround device, the MD120 offers endless possibilities to your part processing needs, including simultaneous part processing, first op / second op processing, or multi-part processing.

Know more

With the power of many machines in one, the MD200 delivers accuracy, efficiency and improved productivity, while reducing the cost of labor.

With drilling and milling in a single setup, this solution provides forward-thinking technology for lean systems and flexible line planning and delivers the power of many machines from a single source.

Know more

Full Line of Twin Opposing Spindle Machines

With the power of two machines in one, the MT12 is equipped with multiple cutting stations and high-precision synchronization, allowing it to turn complex parts in a fraction of the time.

This twin opposing spindle machine is an optimal solution for complex parts such as surgical parts, pumps and valves.

Know more

The MT20 is ultra-versatile for complex parts and is equipped with a 15 station turret on both sides.

With C-axis control on both spindles, this machine offers high-precision synchronization during part transfer, as well as a feed and loader system for unattended operation.

Know more

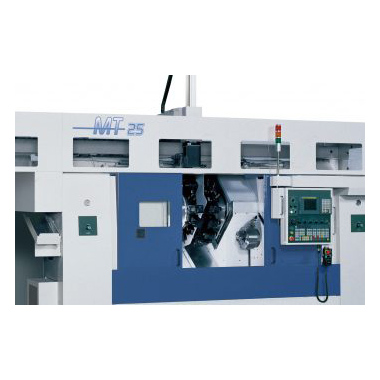

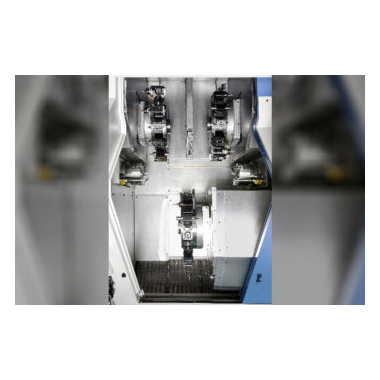

Complete with Y-axis, live tool stations and an optional third turret, the MT25 was specifically designed to turn complex parts.

While parallel spindles allow for higher volume machining, the MT25’s opposing spindles allow it to machine highly complex parts with greater precision than ever before.

Know more

The MT100 is a compact, high-quality turning center with multi-functional capabilities. With a built-in Y-axis, the MT100 allows for greater precision on complex parts and is designed so that each turret can serve either spindle at any time.

Know more

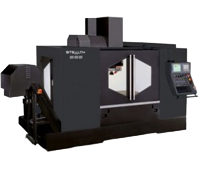

With twin spindles, three turrets and a gantry loader, the MT200 is the ultimate multi-tasker.

By cutting more than one part at once, operators increase productivity while greatly reducing overall cycle time. Learn more about the MT200!

Know more

Full Line of Specialty Machines

A single spindle CNC turning machine, the MJ60 comes equipped with a single 8 station tool turret and hydraulic actuated tailstock.

From shafts, to end pieces and everything in between, the MJ60 offers close tolerance, and can deliver better precision turning than similar models on the market.

Know more

The MJ100 is a specialty machine that was purposefully developed for the automated turning of shaft type production parts that require tight machines tolerances.

Designed to turn longer parts, the MJ100 is a single spindle CNC turning machine with a single turret and optional gantry.

Know more

The MJ200 is a single spindle CNC turning center that was specifically designed for the simultaneous turning of longer parts.

A high-speed machine, the MJ200 offers flexible operation and can perform two identical processes or turnaround solutions, while reducing downtime.

Know more

Designed to turn longer shaft parts, the ML400 up to 400 mm (15.7”) in length and up to 200 mm (7.9″) in diameter. For even longer parts, the machine’s sister model, the ML400L, can turn shaft parts up to 570mm (22.4”) in length and up to 200mm (7.9”) in diameter.

Know more